Even if you’re a casual weekend mechanic, then you’ve undoubtedly heard multiple garage horror stories about what can happen when condensation enters your engine. The good news is that you don’t have to shudder every time it rains; keeping your engine free of damaging contaminants is completely possible. With thorough inspections and routine maintenance, damage due to moisture is a scenario that you can easily avoid altogether.

When it comes to contaminants that can compromise engine efficiency and performance, blow-by is the nemesis of diesel engines. Fortunately, by understanding what causes blow-by and the steps you can take to address it, you can keep this harmful condition at bay.

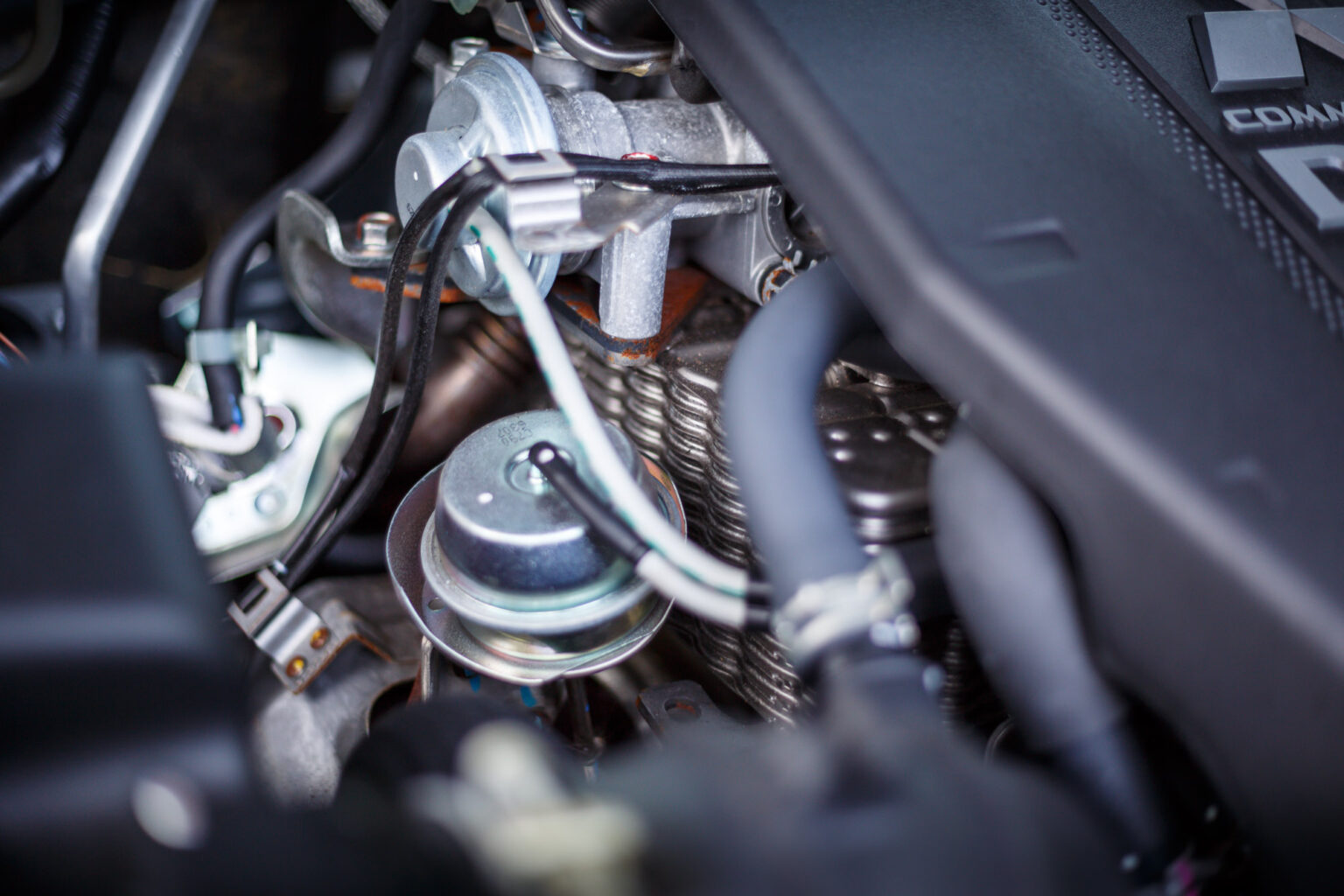

Image: wheelsadviser.com

What is Blow-by?

Diesel engines, due to their compression ignition process and higher combustion pressures than gasoline engines, experience leakage or “blow-by” due to combustion gases forcefully traveling past pistons, rings, and/or cylinder walls. Naturally, this issue needs to be addressed, as the fumes from these “combustion leaks” can harm the engine and other equipment. For instance, blow-by can cause increased crankcase pressure, reduced engine efficiency and power output, higher operating temperatures, turbocharger issues, and a prematurely clogged exhaust system.

How to Diagnose Blow-by

To thoroughly diagnose blow-by, investigate the following:

-

Compression Test:

Regular compression tests will document good compression and compression loss due to escaping combustion gas.

-

Cylinder Leakage Test:

Cylinder leakage tests can determine if there’s leakage past the piston rings.

-

Crankcase Pressure Test:

Crankcase压力测试reveals excessive blow-by, as it measures the amount of combustion gas leaking into the crankcase.

How to Fix Blow-by on a Diesel Engine

Successful remedies for excessive blow-by include:

-

Freshen Up those Rings:

Worn piston rings are a primary culprit for blow-by. In these cases, replacing worn rings and checking for proper ring gap and ring end gap are your best course of action.

-

Inspect Piston-to-Cylinder Clearance:

An oversized piston-to-cylinder clearance can also lead to blow-by. If you suspect this issue, measure the clearance with a bore gauge to verify specs.

-

Check Cylinder Walls for Scoring or Wear:

Cylinder scoring or excessive wear can create blow-by, so these areas should be visually inspected and resurfaced as needed.

-

Assess Head Gasket Sealing:

A failed head gasket can also result in blow-by. If this is the case, head gasket replacement is the appropriate measure.

-

Clean or Replace the PCV Valve and Inspect the CCV System:

A plugged PCV valve can induce blow-by. CCV (crankcase ventilation) system checks will reveal the proper operation of the valve and other CCV system components.

Image: www.motorverso.comTaking Preventative Measures against Blow-by

Keep blow-by in check with these preventative measures:

-

Regular oil changes:

Using high-quality oil and routinely changing it keeps your engine clean and blow-by at bay.

-

Avoid lugging the engine:

Operating a diesel engine at low RPMs or under heavy loads can increase blow-by.

-

Check air filter regularly:

A clogged air filter reduces airflow to the engine, potentially causing blow-by.

-

Turbocharger maintenance:

Regular maintenance of the turbocharger will improve performance and reduce blow-by.

How To Fix Blow By On A Diesel Engine

The Bottom Line

While blow-by is a common issue, it can be successfully addressed and prevented. With proper diagnosis and timely repairs, you can mitigate the detrimental effects of blow-by and ensure the optimal performance of your diesel engine for many years to come.